Understanding Your Pressure Washing Skid

If you're serious about your pressure washing business, you need a professional, reliable, and organized setup. The core of this operation is the Pressure Washing Skid. This comprehensive guide will break down what a skid is, why it's essential, and answer the most common questions to help you invest wisely and dominate the competition.

What is a Pressure Washing Skid?

A pressure washing skid is essentially a turnkey, self-contained washing system mounted on a metal frame, typically made of aluminum or stainless steel. This frame allows the entire unit to be easily loaded into a truck bed, van, or trailer, securing all components in one organized footprint.

Instead of running multiple hoses and struggling to secure tanks and engines separately, a skid offers a unified, compact solution for mobile cleaning services.

Looking for a professional setup? Check out our selection of high-quality Aluminum Truck Skids to get your rig road-ready.

Key Components of a Professional Skid

A high-quality pressure washing skid is built around several critical systems:

- 1. Water Tanks: Typically made of high-density polyethylene (HDPE) to store the water supply. A skid often features multiple tanks: a main water/buffer tank and a chemical tank (for solutions like Sodium Hypochlorite).

- 2. Engine and Pump Units: The heart of the system. Usually features a reliable industrial-grade engine (like Honda or Kohler) and a high-pressure pump to convert power into water flow (GPM) and pressure (PSI).

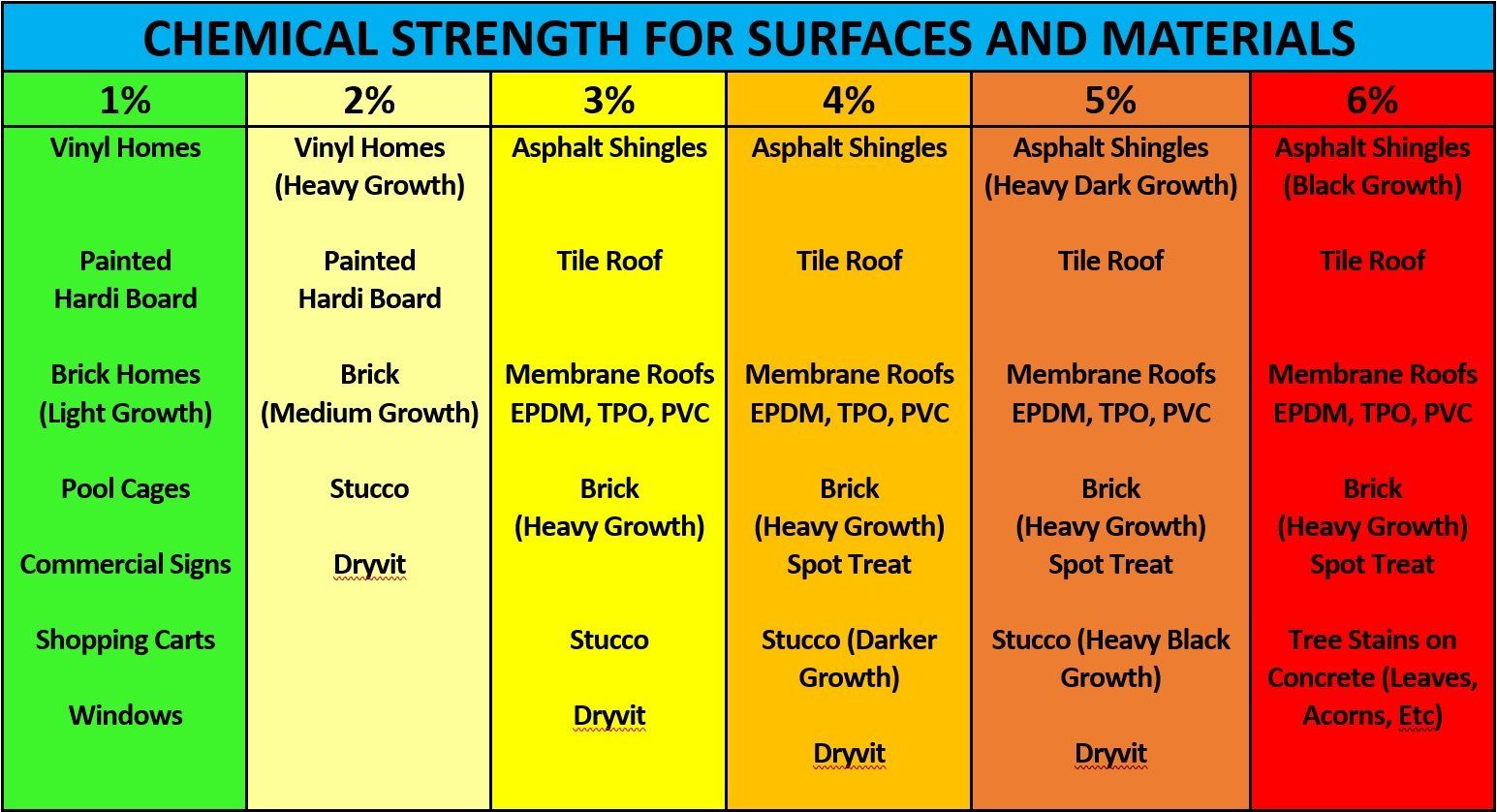

- 3. Chemical Pump (Soft Wash System): Often a separate, dedicated 12V pump used exclusively for soft washing(low-pressure application of chemicals).

- 4. Hose Reels: Critical for efficiency. Skids utilize durable, stackable metal reels to manage and quickly deploy hoses for high-pressure washing, soft washing, and water intake.

- 5. Stainless Steel or Aluminum Frame: The structure that holds everything together. Stainless steel is often preferred for its superior corrosion resistance against water and cleaning chemicals.

Why Invest in a Pressure Washing Skid?

For a mobile operation, the benefits of a purpose-built skid are immense:

- Maximized Efficiency: Everything is right where you need it. Reels make setup and breakdown lightning fast.

- Professionalism: A clean, well-organized skid conveys expertise to your customers.

- Safety and Security: All heavy equipment is securely bolted to a single frame, reducing the risk of damage during transport.

- Durability: Skids are built with corrosion-resistant materials to handle the rigors of daily use.

Frequently Asked Questions (FAQs)

Q1: What is the difference between GPM and PSI, and which is more important?

PSI (Pounds per Square Inch) measures the force of the water stream, effective for blasting away hard stains. GPM (Gallons Per Minute) measures the volume of water. GPM is generally more important for professionals because it dictates the speed and rinse power. An 8 GPM machine cleans faster than a high-PSI, low-GPM unit.

Q2: Should I get an aluminum or a stainless steel skid frame?

Stainless Steel offers the highest resistance to corrosion from bleach and salt. Aluminum is lighter, which is beneficial for weight restrictions. If you need lightweight durability, explore our Aluminum Truck Skids designed to balance strength and weight.

Q3: What is "Soft Washing," and does my skid need it?

Soft Washing uses low pressure combined with specialized detergents to clean delicate surfaces like roofs and siding. Yes, your skid should include a soft wash system to offer comprehensive services without damaging delicate surfaces with high pressure.

Q4: How do I prevent my skid's pump from overheating?

Overheating occurs when the pump runs with the trigger gun closed. To prevent this: install a Temperature Relief Valve (TRV), use a time delay shutdown, and never leave the pump running unattended for more than a few minutes.

Q5: What size of water tank should I put on my skid?

You generally want enough buffer capacity to run for 5 to 10 minutes without immediate supply. For an 8 GPM machine, a tank of 100 gallons or more is recommended to ensure consistent flow, especially when residential water supplies cannot keep up.